Petronor Technical Shutdown June 2024

During the two-month shutdown, highly complex technical maintenance work will be carried out using the most innovative and efficient technologies in the industrial sector.

As far as we are concerned, we are participating with a team of 18 people and with our largest cranes: Liebherr LTM 1750 and LTM 650, together with other smaller cranes and different trucks, up to a total of 16 vehicles.

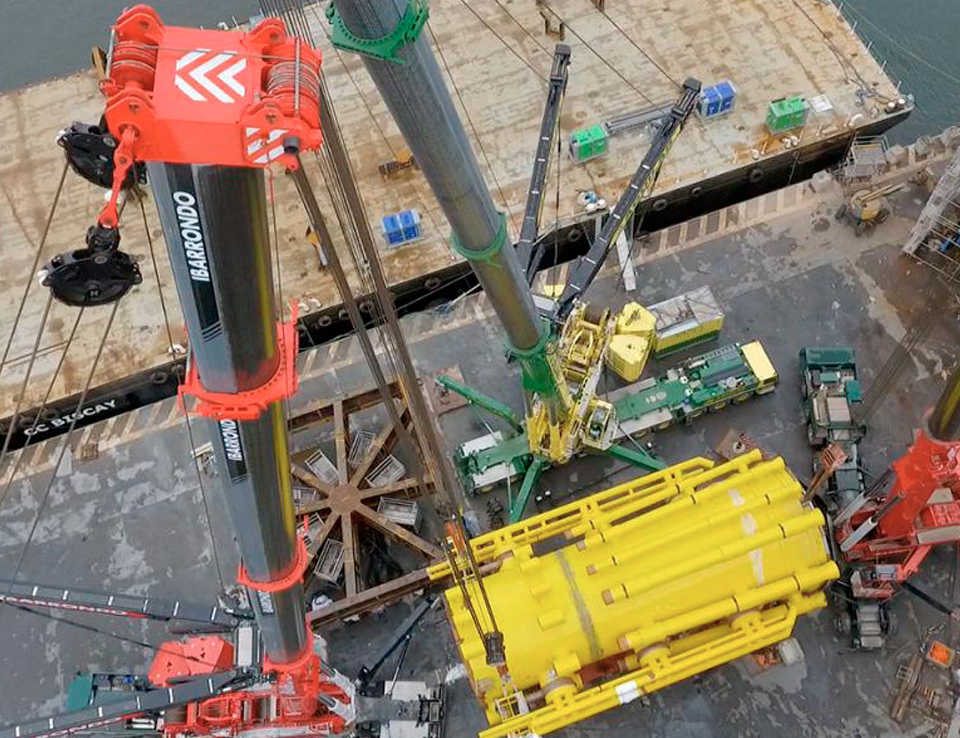

Off-shore wind power plant

Ship loading manoeuvre of large equipment for the off-shore wind power plant. Liehberr LG 1.750 crane.

A manoeuvre which involved moving and assembling two parts which together weighed almost 1,000 tonnes.

Off-shore wind power equipment for a wind farm in Belgium fully constructed in Navacel, Erandio.

The first phase of the manoeuvre involved raising a 290-tonne cylinder to a vertical position and placing it on a bench.

In this phase we used 2 Liebherr LTM-1.750.9 and 1 Demag AC 700. The cranes were hooked for 2 days, 24 hours a day. A total of 16 people participated in this phase.

The second part of the manoeuvre involved hoisting a 330-tonne platform and placing it on the cylinder which had been positioned during the first phase.

This manoeuvre was carried out with 4 cranes: 2 Liebherr LTM 1750.9, 1 Demag AC 700 and 1 Liebherr LTM 1500.8. It took three days in 24-hour shifts and required a team of 18 people.

SidenorDescription:One of the Group´s main activities is Industrial. A kind of handling quite complex because them are carried out in small and limited maneuverability spaces.

In the Sidenor´s factory wich is located in the biscayan town of Basauri, we manage the location of a new industrial water tank in its definitive place. A large cistern, 50 meters long and 70 tons in weight, built in horizontal.

The intervention of two cranes were required by the handling: a Liebherr LTM 1.750-09.1 and an LTM 1.350.

LTM1300-6.2 of 300 t to take several piping sections and a 35-tonne electrofilter about 18 m away, using 96 tonnes of counterweight to carry out the manoeuvre. Once the old electrofilter had been disassembled, the new one was assembled, piece by piece, in the same place, since it was not possible to place it fully assembled due to the difficulty involved.

The intervention of two cranes were required by the handling: a Liebherr LTM 1.750-09.1 and an LTM 1.350.

Customer: FPK Lightweight Technologies

If there is one thing that characterizes Ibarrondo Group, it is their high technical capacity to offer lifting solutions. On this occasion, it was a spectacular manoeuvre to introduce a 165-ton through the ceiling of FPK Lightweight Technologies production plant in Zamudio.

The complex manoeuvre required 3 cranes: Liebherr 500 t, Demag 500 t, Demag 750 t as well as other support equipment, Liebherr LTM 1030, transport trucks, etc…

The 165-ton press was raised up to 22 metres from the ground so as to be introduced into the building through the ceiling. A technical team of 16 people from Ibarrondo Group performed the whole manoeuvre. Moreover, our technical department fully developed the project and the simulation so that all the work was carried out to the letter and within the needs specified by the client.

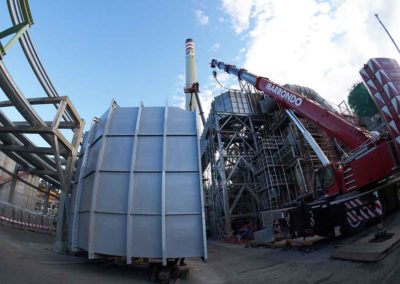

A large industrial space such as a refinery needs great adaptability as for the amount and volume the machines can load. The Ibarrondo Group perfectly embodies all these qualities.

During the shutdown of Petronor’s refinery in Muskiz for the maintenance of diverse industrial equipment in January and February 2015, a permanent team of 25 people dealt with the 12 cranes of various lifting capacities which participated in the maintenance work.

A prestigious company such as Cadenas Vicinay fully relies on the capabilities of the Ibarrondo Group to deal with their renowned products. 500-kilo links which are sometimes part of chains of up to 500 tons are loaded onto vessels so as to be sent to anywhere in the world.

Loading is carried out by two cranes, Demag AC 500 and Liehberr LTM 500, which introduce the chain in stages into the hold of the vessel. Around 1,000 tons are moved every day. This operation takes place several times a year.

Guarantee the next operational cycle. This was the aim sought with the technical shutdown carried out by the largest refinery of the State between February and March 2017.

Petronor has invested 49 million Euros in inspection, revision and improvement works in 75% of its facilities in Muskiz. It has been the largest shutdown in the history of the refinery since it was established in 1969.

During the six weeks that the shutdown has lasted, a team of 50 people from the Ibarrondo Group have been working inside the refinery.

The means used included several 30 to 750 tonne cranes and various trucks, up to a total of 30 vehicles.